Contact us

+86-15383080480 (Wechat)

West side of Jianshe Road, South side of Yongtai Road, Jizhou City, Hengshui City, China

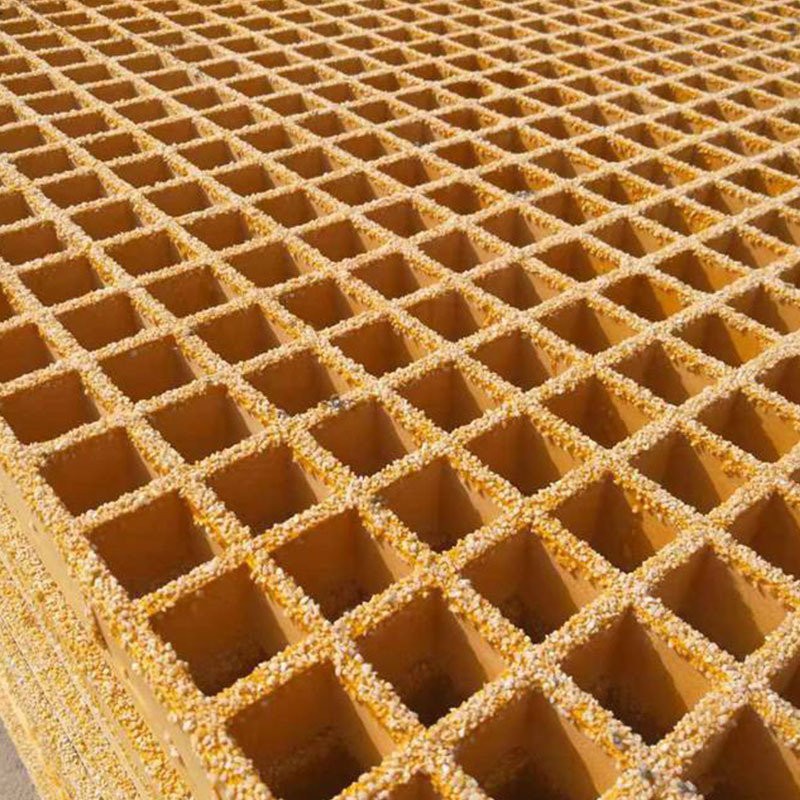

FRP grating

- Description details

-

Product specifications and services of FRP grating

1. Common specifications

Grate size: common 1220×3660mm, 1000×4000mm, etc., can be customized.

Grate thickness: 25mm, 30mm, 38mm, 50mm, etc., optional for different load-bearing requirements.

Grid size: 19×19mm, 38×38mm, 50×50mm, etc., affecting drainage and anti-slip performance.

Color selection: yellow, green, gray, red, etc., corporate colors can be customized.

2. Customized service

Provide special-shaped cutting, punching, edging and other processing services.

Support special resin formulas (such as high temperature resistance, flame retardant, UV resistance, etc.).

Provide installation guidance and after-sales maintenance support.

Main Use

FRP grating is a lightweight, high-strength material made of glass fiber and resin. It has corrosion resistance, anti-slip, insulation and other characteristics. It is widely used in many industries. The following are its main uses:

1. Industrial field

Petrochemical: used for platforms, walkways, around storage tanks, resistant to acid, alkali and corrosive gases.

Power industry: substations, cable trench covers, insulation and anti-electric shock.

Sewage treatment: replace metal gratings, used for pool covers, maintenance channels, corrosion resistance.

2. Construction and municipal

Commercial buildings: stair treads, corridors, roof platforms, light and beautiful.

Municipal facilities: pedestrian bridges, gutter covers, tree pool covers, rust-proof and good load-bearing.

Offshore platforms: docks, ship decks, resistant to salt spray corrosion.

3. Transportation

Vehicle parts: truck bottom plates, rail transit walkways, weight reduction.

Airport facilities: terminal passages, maintenance platforms, fire retardant.

4. Environmental protection and energy

Environmental protection equipment: waste gas treatment tower, garbage station work platform.

New energy: wind power platform, solar bracket structure.

5. Other special scenarios

Food and medicine: workshop floor, in line with hygiene standards.

Military/aerospace: temporary runway, equipment bracket, high strength and lightweight.

Core advantages

Corrosion resistance: suitable for chemical environment.

Lightweight and high strength: easy installation and good load-bearing capacity.

Safety and anti-slip: the surface can be designed with patterns or anti-slip sand layer.

Insulation and non-conductive: suitable for power places.

The selection needs to be customized according to the load, size and environment (such as temperature resistance and UV protection).

Application areas of FRP Grating

Chemical industry: used in corrosive environments such as pickling workshops, electroplating plants, chemical plants, etc.

Sewage treatment: used as sewage pool cover and walkway grating, corrosion-resistant and easy to clean.

Oil platform: offshore drilling platform walkways, non-slip pedals, resistant to salt spray corrosion.

Food processing: suitable for humid, easy-to-clean environments, FDA compliant.

Transportation facilities: non-slip walkways in subway stations, airports, docks, etc.

Power industry: substation insulation grilles, cable trench covers, etc.

Contact Us

Keywords: