Contact us

+86-15383080480 (Wechat)

West side of Jianshe Road, South side of Yongtai Road, Jizhou City, Hengshui City, China

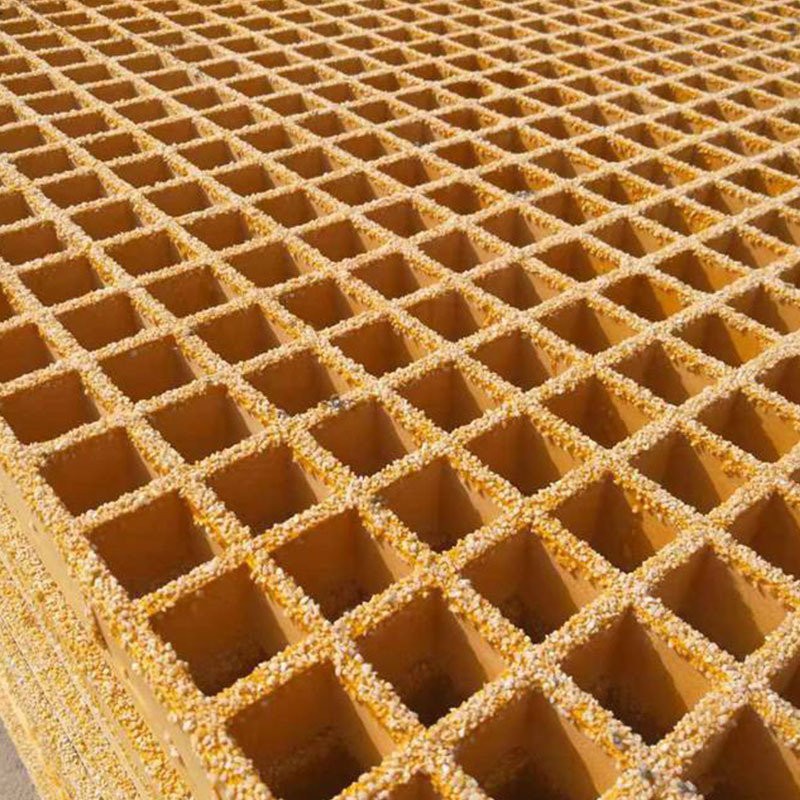

FRP Grating For ETP STP Plants

- Description details

-

The Ultimate Corrosion-Resistant Solution

Fiber Reinforced Plastic (FRP) grating is a highly durable, lightweight, and corrosion-resistant material widely used in Effluent Treatment Plants (ETP) and Sewage Treatment Plants (STP). Due to its exceptional resistance to chemicals, moisture, and harsh environments, FRP grating for wastewater treatment has become a preferred alternative to traditional steel and aluminum gratings.

In this comprehensive guide, we will explore the benefits, applications, types, and installation methods of FRP grating in ETP/STP plants, along with key factors to consider when selecting the best grating for your project.

ETP and STP plants operate in highly corrosive environments due to exposure to chemicals, sewage, acids, alkalis, and moisture. Traditional metal gratings deteriorate quickly, leading to high maintenance costs. FRP grating offers several advantages:

Superior Corrosion Resistance

High Strength-to-Weight Ratio

Slip-Resistant & Safety Compliant

Low Maintenance & Long Lifespan

Electrically Non-Conductive & Fire Retardant

Applications of FRP Grating in ETP & STP Plants

Walkways & Platforms: Provides safe access for maintenance personnel, Resistant to chemical spills and moisture

Drain Covers & Trench Grating: Prevents clogging while allowing easy water flow,Corrosion-proof even in high-moisture areas

Stair Treads & Catwalks: Slip-resistant even when wet,Lightweight yet durable for heavy foot traffic

Biogas & Chemical Storage Areas: Withstands H2S, methane, and corrosive gases,No degradation from sewage fumes or industrial chemicals

Clarifiers & Aeration Tanks: Used as support structures and protective covers,

Resistant to algae, bacteria, and biofilm buildup

Contact Us

Keywords: