Contact us

+86-15383080480 (Wechat)

West side of Jianshe Road, South side of Yongtai Road, Jizhou City, Hengshui City, China

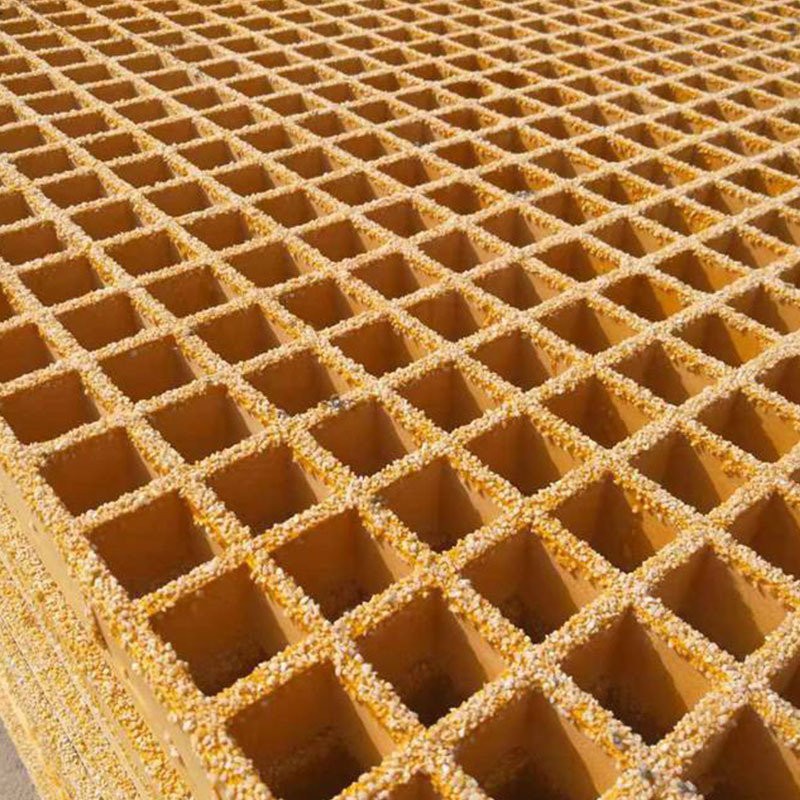

FRP Pultruded Grating

- Description details

-

Pultruded FRP grating is a structural material made of fiber reinforced plastic (FRP) through pultrusion process. With glass fiber as the reinforcing material and resin as the matrix, it is formed into a plate or profile with a uniform grid structure through pultrusion molding in a specific mold.

Production Process

● Glass Fiber Pre-Impregnation: Immerse glass fibers into an impregnation tank containing resin and additives.

● Pultrusion Molding: The pre-impregnated fibers pass through a mold, and under the traction of a pultrusion machine, the fibers and resin cure and form in the mold.

● Curing and Cooling: During pultrusion, the resin undergoes a curing reaction at high temperature to form a stable three-dimensional network structure, enabling the grating to obtain the required mechanical properties. Subsequently, the preliminarily formed grating is cooled by a cooling system to reduce its temperature to room temperature, ensuring dimensional stability.

● Cutting and Post-Processing: Cut the cooled finished product according to the design dimensions to obtain the required length and width. Meanwhile, carry out edge grinding to remove burrs and uneven parts, and perform subsequent processes such as anti-slip treatment, such as coating anti-slip coatings or laying anti-slip sand particles.Product Features

● Corrosion Resistance: Capable of withstanding corrosion from gaseous and liquid media such as acids, alkalis, organic solvents, and salts at different concentrations.

● Lightweight and High Strength: With a specific gravity 1/4 that of steel, its high glass fiber content (over 60%) endows it with outstanding specific strength and specific stiffness in the unidirectional direction.

● Flame Retardancy: The oxygen index (OI) is generally above 33, and the flame spread rate is <25. The OI of phenolic pultruded grating can reach up to 100.

● Impact and Fatigue Resistance: Exhibits high impact strength, allows repeated bending without permanent deformation, and its moderate elasticity ensures comfortable working conditions for personnel.

● Slip Resistance: The surface is pre-designed with linear anti-slip grooves, and anti-slip effect can also be enhanced by laying sand with adhesives.

● Aging Resistance: Manufactured with high-quality resin and glass fiber systems, it has a service life of over 20 years, and retains more than 85% of its strength after 20 years.

● Aesthetic and Easy Maintenance: Features bright colors that are not prone to fading, requires no painting, and has a self-cleaning effect.

● Safety: Possesses excellent electrical insulation, no electromagnetic properties, and no sparking.

Dimension Parameters

Common grating plate sizes include 1000mm×3000mm, 1220mm×2440mm, etc.

Common grid sizes include 38mm×38mm, 40mm×40mm, 50mm×50mm, etc., and can be customized according to actual needs.

Product Parameters

Physical Performance Parameters

Density: Typically 1.5–2.0 g/cm³.

Thermal Expansion Coefficient: Relatively low, generally between 0.8×10⁻⁶/K and 1.2×10⁻⁶/K .

Temperature Resistance Range: The normal service temperature range is usually - 40℃ to 120℃. Special resins can enhance high-temperature resistance, with certain models capable of withstanding up to 150°C.

Water Absorption Rate: Usually less than 1%.

Mechanical Performance Parameters

Tensile Strength: Typically between 200-400MPa, with vinyl ester resin and epoxy resin gratings exhibiting higher tensile strength.

Bending Strength: Approximately 400-700MPa.

Shear Strength: Generally 50-100MPa.

Elastic Modulus: Typically 20-40GPa.

Impact Strength: Generally 100-150KJ/m².

Application Scenarios

Pultruded gratings find wide applications:

In chemical and petrochemical industries for corrosion-resistant platforms and trenches.

In marine engineering for offshore platforms and port facilities.

In construction as anti-slip flooring and roofing materials.

In the power sector for insulated walkways.

In transportation for railway and bridge components.

In scenarios like swimming pool perimeters and sewage treatment plants.

They meet diverse needs with properties like corrosion resistance and lightweight high strength.

Contact Us

Keywords: