Contact us

+86-15383080480 (Wechat)

West side of Jianshe Road, South side of Yongtai Road, Jizhou City, Hengshui City, China

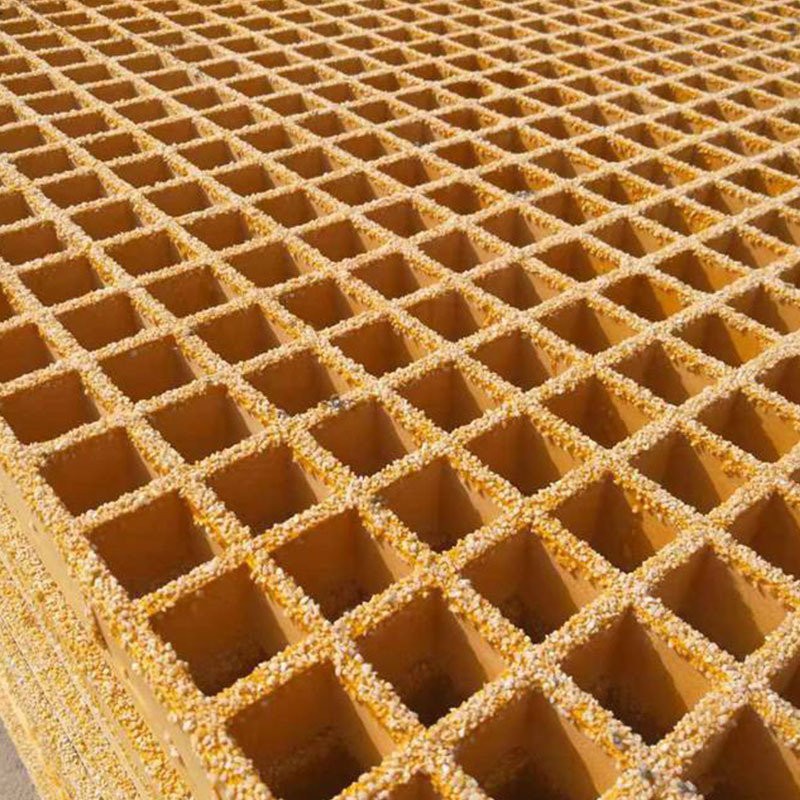

FRP Grating with anti-slip cover

- Description details

-

FRP Grating with anti-slip cover

3mm deep diamond anti-skid pattern + surface frosting process, the friction coefficient in wet and slippery environment reaches 0.85 (national standard ≥0.5), and it is still anti-skid as before in oily environment.

Compression and impact resistance: bearing strength ≥5 tons/㎡, resistant to instantaneous impact without fragmentation, suitable for heavy machinery high-frequency rolling scenes.

Sealed zero penetration, corrosion-resistant all-weather

▷Seamless splicing: customized buckle design, sealing strips filled at the seams, completely blocking liquid and gas leakage, protection level IP68.

▷ Chemical immunity: resistant to strong acid (pH1-14), salt spray, and organic solvent corrosion, with a service life of up to 25 years* (traditional steel plate life <8 years).

Lightweight intelligent manufacturing, installation and load reduction

Weight reduction of 70%: The density is only 1/4 of steel, and one person can carry it, and the construction efficiency is increased by 2 times.

Maintenance-free design: rust-proof, crack-proof, and non-conductive, and the annual comprehensive maintenance cost is reduced by 90%.

Main Use

“Where the danger is, there is the line of defense”

Chemical plant walkway: acid and alkali corrosion resistance + explosion-proof design to protect the safety of patrol personnel;

Offshore platform deck: salt spray resistance + UV resistance, facing strong winds and waves without deformation;

Food workshop: seamless anti-bacterial leakage, passed FDA food grade certification;

High-altitude fire passage: flame retardant grade V0, no brittleness at extreme temperature differences from -50℃ to 120℃

Application areas of FRP Grating

Chemical industry: used in corrosive environments such as pickling workshops, electroplating plants, chemical plants, etc.

Sewage treatment: used as sewage pool cover and walkway grating, corrosion-resistant and easy to clean.

Oil platform: offshore drilling platform walkways, non-slip pedals, resistant to salt spray corrosion.

Food processing: suitable for humid, easy-to-clean environments, FDA compliant.

Transportation facilities: non-slip walkways in subway stations, airports, docks, etc.

Power industry: substation insulation grilles, cable trench covers, etc.

Production Process of FRP Grating

The production of FRP grating mainly adopts the following processes:

Molding: After mixing glass fiber and resin, put them into the mold for high temperature and high pressure curing and molding, which is suitable for standard specification gratings.

Pultrusion molding: Produce grating profiles through pultrusion process, and then assemble them into grating plates, which are suitable for high-strength demand scenarios.

Hand lay-up molding: Suitable for customized special-shaped gratings, which are cured and molded after manual laying.

Vacuum infusion: The resin evenly penetrates the fiber under vacuum environment to improve the density and strength of the product.

Contact Us

Keywords: