Contact us

+86-15383080480 (Wechat)

West side of Jianshe Road, South side of Yongtai Road, Jizhou City, Hengshui City, China

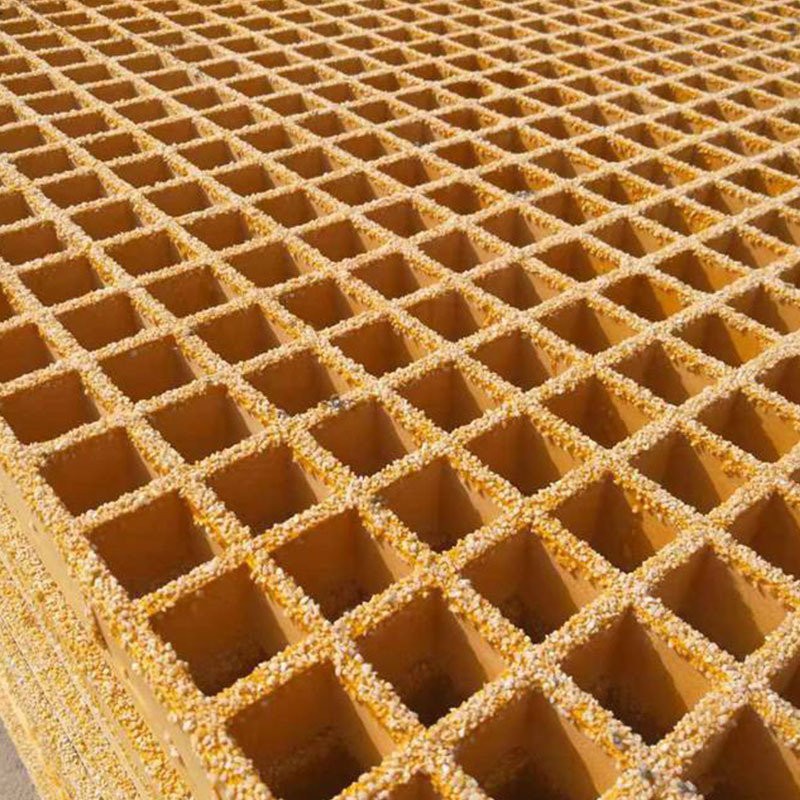

FRP Grating for Solar Project Walkway

- Description details

-

FRP Grating Walkway‘s design, installation and purchasing guide for solar project

Selection of FRP grating specifications:

Thickness: The mainstream choice is 25mm (load-bearing ≤1 ton/㎡) or 30mm (load-bearing ≤3 tons/㎡), which needs to be determined according to the load of the photovoltaic array operation and maintenance vehicle or personnel.

Hole spacing: 38×38mm (excellent anti-slip performance) or 40×40mm (higher light transmittance), and the hole type is recommended to choose micropores to enhance anti-slip performance.

Color: Yellow-green (warning function) or gray (dirt-resistant) is recommended, and an anti-ultraviolet coating can be added to the surface to extend the outdoor service life.

Material: Flame-retardant resin (oxygen index ≥28) and alkali-free glass fiber must be selected to avoid fire risks in photovoltaic areas.

Processing precautions:

Cutting: It is recommended to use diamond cutting blades (thickness ≥2mm) to avoid fiber stratification. A 5mm margin should be reserved for the incision, and a resin edge sealant (such as epoxy resin) should be used to treat the cross section after grinding to prevent water absorption and aging.

Drilling: When the hole diameter is greater than 12mm, a stepped drill bit should be used, and the drilling speed should be controlled below 500rpm to avoid glass fiber drawing. The hole edge should be chamfered (R≥1mm) and sealed with glue.

Grinding: Use 80-120 grit sandpaper or tungsten steel grinding head to deal with burrs. The grinding direction should be along the grille texture to reduce fiber exposure.

Installation technical points:

Fixed method:

Type of clamp:

M-type clamp (applicable to 25mm thick grille, bolt spacing ≤400mm)

L-type clamp (edge fixed, stainless steel self-tapping screws STS4.8×25 are required)

C-type clamp (used for cantilevered parts, wind load resistance needs to be verified)

Connector material: 304 stainless steel is recommended (316 stainless steel is required in coastal areas).

Support frame:

When the span is ≤1.2m, glass fiber reinforced plastic beams (cross section ≥50×50mm) can be used;

The steel frame needs to absorb vibration.

Procurement suggestions:

Certification requirements: Products must provide ISO 9001 certification and SGS anti-aging test report (3000 hours QUV test).

Cost control:

For bulk purchases (≥500㎡), the manufacturer can be required to directly reserve installation holes during molding to reduce on-site processing costs.

Logistics protection:

It needs to be placed vertically during transportation, and EPE pearl cotton pads are used between layers to avoid lamination deformation.

Special environment response:

Salt spray environment: Choose vinyl ester resin-based grilles, and the fixtures must pass a 480-hour neutral salt spray test.

Cold regions: Use low-temperature resin (-60℃ impact strength retention rate ≥ 80%).

If specific load calculation or installation plan optimization is required, it is recommended to provide a project geological survey report and photovoltaic array layout diagram for special design.

Contact Us

Keywords: