Contact us

+86-15383080480 (Wechat)

West side of Jianshe Road, South side of Yongtai Road, Jizhou City, Hengshui City, China

FRP Fencing Handrail Ladder

- Description details

-

Product Introduction

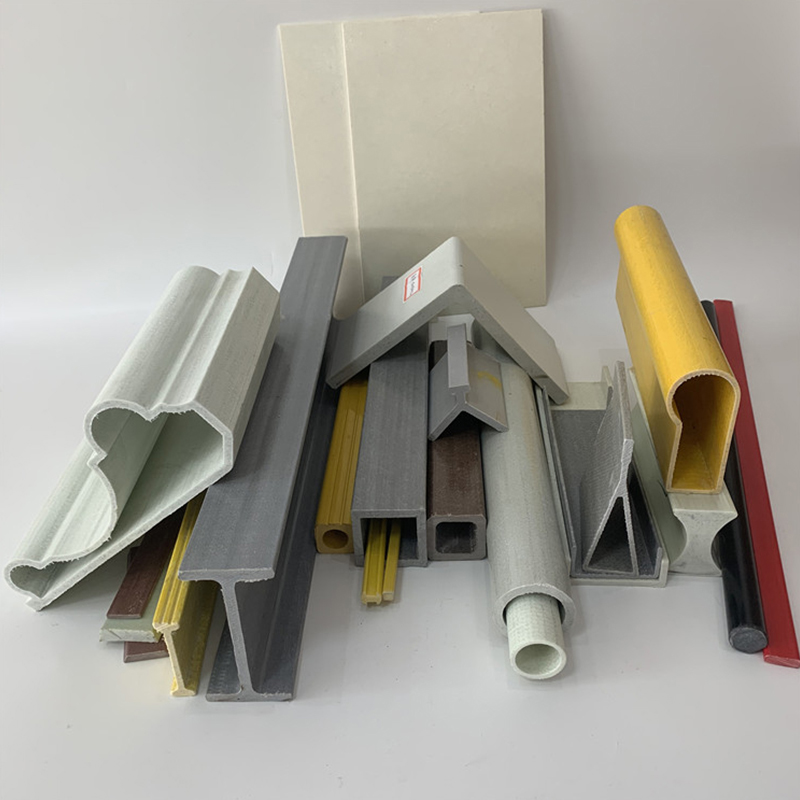

FRP pultruded profile fence: a durable, beautiful, low-maintenance modern fence solution

FRP pultruded profile fence (also known as FRP pultruded fence or composite fence) is a new type of fence product that has rapidly emerged in the fields of building fences, industrial guardrails and municipal facilities in recent years. As an ideal alternative to traditional metal fences and wooden fences, fence profiles manufactured by FRP pultrusion molding process are being widely used in various engineering projects due to their excellent weather resistance, corrosion resistance and long life.

FRP pultruded fence is made of fiberglass reinforced plastic (FRP) through pultrusion process, which can produce continuous length profiles with constant cross-sectional shape. Compared with traditional fence materials, FRP pultruded profile fence has significant advantages such as light weight, high strength, maintenance-free and easy installation. It is particularly suitable for use in highly corrosive environments such as coastal areas, chemical plant areas, and sewage treatment plants.

Product performance and advantages

1. Excellent physical properties

High strength: Strong impact resistance, more than 1.5 times that of ordinary steel, not easy to deform.

Lightweight: The density is only 1/4 of that of steel, which is easy to transport and install.

Corrosion resistance: Not affected by acid, alkali, salt, and humid environment, suitable for harsh conditions such as coastal and chemical industries.

2. Excellent weather resistance

UV resistance: Add UV stabilizer, long-term exposure will not fade or crack.

Wide temperature range: -50℃~120℃ stable performance, suitable for extreme climates.

3. Safe and environmentally friendly

Insulated and non-conductive: suitable for substations, communication base stations and other places.

No heavy metal pollution: meets environmental protection standards and can be recycled.

4. Economical and practical

Maintenance-free: no need for paint or rust-proof treatment, service life of more than 20 years.

Convenient installation: modular design, can be quickly spliced, reducing labor costs.

5. Beautiful and diverse

Customizable colors and textures (imitation wood, imitation stone, metal texture, etc.).

Provide a variety of styles (hollow, solid, combined, etc.).

Application fields

Municipal engineering: road isolation belts, bridge guardrails, park trail fences.

Industrial field: chemical plants, sewage treatment plants, power facility protection fences.

Civil buildings: community walls, balcony guardrails, villa courtyard enclosures.

Garden landscape: scenic trails, wetland parks, ecological wooden plank road guardrails.

Traffic facilities: highway sound barriers, subway platform isolation fences.

Size specifications

Fiberglass fences can be customized according to needs, and common standard specifications are as follows:

Parts Size (mm) Remarks

Posts 80×80, 100×100, 120×120 Height is usually 1.0m~2.5m

Crossbars 40×40, 50×30 Length 1m~6m (can be spliced)

Guardboard Width 200~600, thickness 3~8 Hollow or solid design

Overall height 800~2500 Can be adjusted according to safety requirements

Why choose our fiberglass fence?

Strict quality control: imported resin and high fiber materials are used to ensure product consistency.

Customized service: support drawing or sample customization to meet personalized needs.

Fast delivery: standardized production + flexible customization, shortening the delivery cycle.

After-sales guarantee: provide 10-year warranty and lifelong maintenance support.

Conclusion

FRP fences are gradually replacing traditional fence materials with their corrosion resistance, high strength, beautiful and environmentally friendly characteristics. Whether it is a harsh industrial environment or a high-demand landscape project, it can provide long-lasting and reliable protection and decorative effects. Welcome to contact us for samples or customized solutions!

FAQ

Q1: What is the load-bearing capacity of FRP fences?

A1: The lateral load-bearing capacity of standard FRP fences can reach 50-100kg/m, which can be further improved by strengthening the design. The bending strength of the column is usually more than 2000N·m, which meets the needs of most application scenarios.

Q2: Will FRP fences fade?

A2: High-quality products use UV-resistant fence formulas, and the color stability can reach above level 8 (according to ISO gray card standards), and there is no obvious fading in 10 years. Low-end products may fade after 3-5 years.

Q3: Are special tools required to install FRP fences?

A3: Basic installation only requires conventional tools such as electric drills and wrenches. Fence installation accessories are usually designed as standardized interfaces, and no special equipment is required. Complex projects may require professional measuring instruments to ensure accuracy.

Q4: Can FRP fences be recycled?

A4: FRP materials are theoretically recyclable, but the recycling system of environmentally friendly fences is still being improved. Some manufacturers provide recycling services, and the old fences are broken into pieces and used as fillers for low-demand products.Q5: How to judge the quality of fiberglass fences?

A5: You can use the following simple tests:

Knocking sound: crisp and uniform is good, dull may have holes

Cross-sectional observation: fiber distribution is uniform, no resin accumulation

Bending test: moderate bending should be able to rebound without cracks

Burning test: Flame retardant type should extinguish itself when away from fire (manufacturer guidance required)

Contact Us

Keywords: