Contact us

+86-15383080480 (Wechat)

West side of Jianshe Road, South side of Yongtai Road, Jizhou City, Hengshui City, China

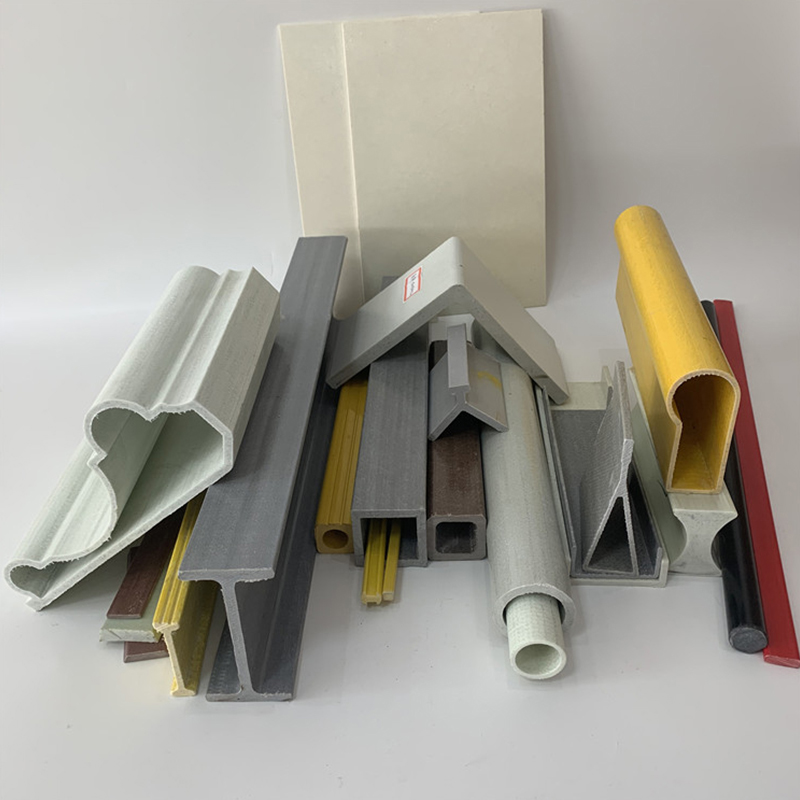

FRP/GRP U/C Channel

- Description details

-

Feature and Advantage

Corrosion resistance: can withstand acid, alkali, salt, and organic solvents for a long time, replacing 304 stainless steel (the first choice in the chemical industry);

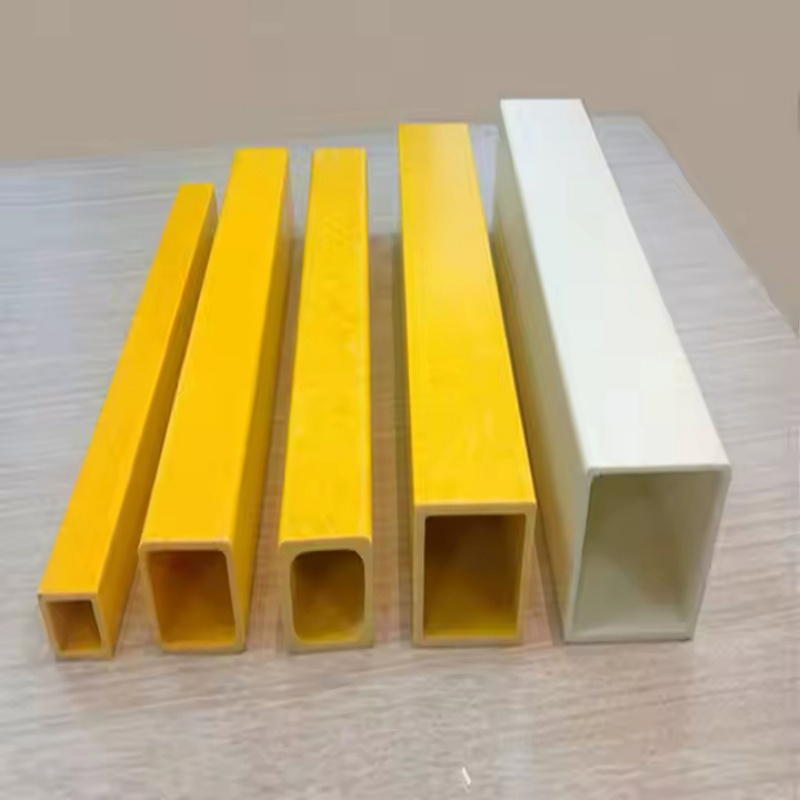

Lightweight and high-strength: density is only 1/4 of steel, tensile strength ≥300MPa;

Insulation and flame retardant: oxygen index ≥28, suitable for power and flammable environments;

Maintenance-free: 20-year service life, reducing overall costs.

Product specifications and services of FRP Profiles - Round Tube

odel No. Height(mm) Leg Width(mm) Waist Thickness(mm) Standard Length FRP-50×37×4.5

50

37

4.5

6m/ Customized

FRP-100×48×5.3

100

48

5.3

6m/ Customized

Support non-standard customization: special sections, reinforcement ribs, embedded parts, colors (RAL color card optional).

Customized Service Process

Design on demand: provide CAD drawing optimization and load calculation support;

Special process:

Flame retardant/antistatic modification;

Surface texture treatment (anti-slip/matte);

Quick response: 7-15 days delivery, support small batch trial orders.

High-temperature resistant FRP profile production technology, high-precision FRP profile manufacturing core technology: FRP channel steel pultrusion molding technology

Raw materials: high-purity resin (vinyl/epoxy/unsaturated polyester) + alkali-free glass fiber yarn

Production process:

Impregnation: The fiber is evenly impregnated with resin to ensure the density of the material;

Molding: Continuous pultrusion molding through high-temperature molds to accurately control the cross-sectional dimensions;

Curing: Segmented curing improves mechanical properties and avoids deformation;

Cutting: Cutting by automated equipment, tolerance ≤±1mm.

Technical advantages:

Integrated structure without welds, strength increased by more than 30%;

Customized anti-UV layer to extend outdoor service life

Application areas of FRP Profiles - U/C Channel

1. Typical application scenarios

Chemical corrosion protection: pickling workshop bracket, tank platform structure;Power engineering: cable tray, insulated ladder;

Wastewater treatment: aeration tank grille, anti-corrosion railing;

Marine engineering: dock fender, desalination equipment bracket.

2. Finished products that can be processed

Structural support parts: I-beam, angle steel, U-shaped groove combination frame;Functional profiles: anti-slip treads, cable trays, equipment bases.

Contact Us

Keywords:

Related Products

(Direct sales from the manufacturer | Customization supported | Corrosion-resistant FRP tube)

FRP rectangular tubes and square tubes are lightweight and high-strength structural materials made from fiberglass reinforced plastic (FRP) through pultrusion. They are widely used in corrosive environments such as chemical industry, electric power, and marine engineering, replacing traditional metal pipes and solving industry pain points such as rust and aging.