Contact us

+86-15383080480 (Wechat)

West side of Jianshe Road, South side of Yongtai Road, Jizhou City, Hengshui City, China

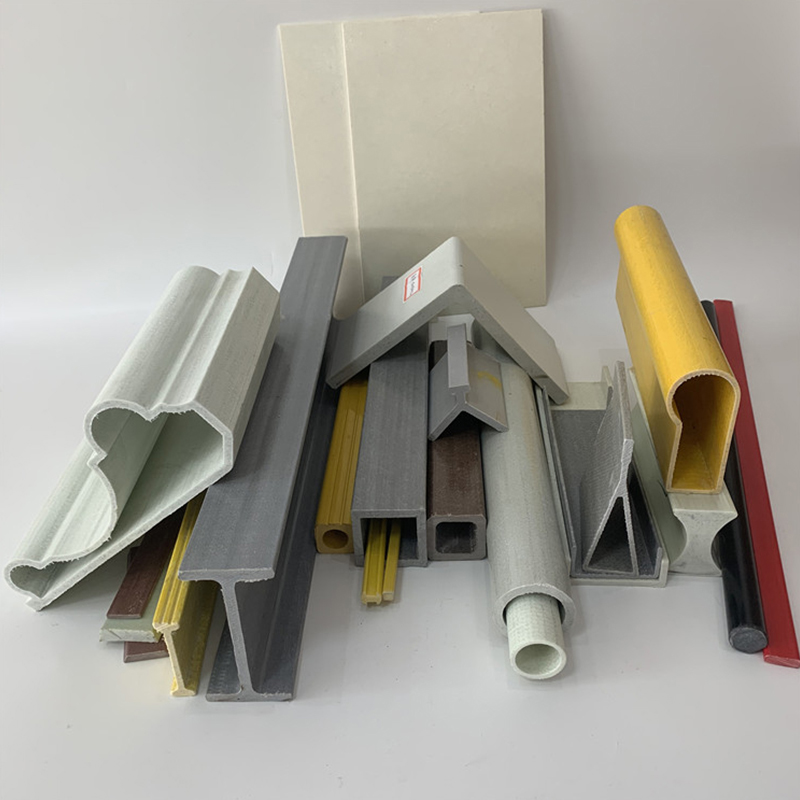

FRP/GRP Square/Rectangular Tube

(Direct sales from the manufacturer | Customization supported | Corrosion-resistant FRP tube)

FRP rectangular tubes and square tubes are lightweight and high-strength structural materials made from fiberglass reinforced plastic (FRP) through pultrusion. They are widely used in corrosive environments such as chemical industry, electric power, and marine engineering, replacing traditional metal pipes and solving industry pain points such as rust and aging.

- Description details

-

Feature and Advantage

Strong corrosion resistance: can withstand acid, alkali, salt, organic solvents and other media, with a service life of more than 20 years (3-5 times that of metal pipes).

Light weight and high strength: the density is only 1/4 of steel, and the tensile strength is ≥300MPa.

Insulation and anti-static: the surface resistance can be customized to 10³~10⁸Ω to meet the requirements of explosion-proof environment.

Low maintenance cost: no painting, no scaling, and the annual maintenance cost is reduced by more than 60%.

Product features and performance parameters

1. Core performance

Lightweight and high strength: density 1.6-2.0g/cm³, strength 2-3 times that of steel, tensile strength ≥300MPa.Corrosion resistance: can withstand acid and alkali environments with pH 3-11, and no corrosion after 5000 hours of salt spray test.

Insulation and flame retardant: dielectric strength ≥15kV/mm, oxygen index ≥28 (UL94 V-0 grade).

Long life: outdoor service life ≥20 years, maintenance-free cost.

2. Dimensions (customization supported)

Type Regular Size(mm) Wall Thickness(mm) Length(m) FRP Square Tube 20×20 – 400×400 3-20 6/12 Rectangular Square Tube 50×30 – 500×200 5-25 6/12 Customized Service Process

Customized service and delivery guarantee

Flexible customization: support non-standard size (±5% adjustment), color (RAL color card optional), surface texture (glossy/matte).

Fast delivery: regular products are shipped within 7 days, and urgent orders are responded to within 72 hours.

Quality inspection standards: third-party inspection reports are provided for each batch (including mechanical properties and corrosion resistance tests).

Application areas of FRP Profiles-Round Tube

Chemical and environmental protection: acid mist purification tower bracket, sewage treatment pool guardrail (replacement of 316L stainless steel).

Marine engineering: desalination pipeline, dock anti-corrosion grille (resistant to salt spray corrosion).

Power communication: cable tray, insulated ladder (flame retardant insulation properties).

Rail transit: subway ventilation ducts, platform anti-collision columns (lightweight design).

Production process and technical advantages

1. Core process: pultrusion technology

Raw materials: high-purity resin (epoxy/unsaturated polyester) and alkali-free glass fiber are mixed in precise proportions.Process: fiber dipping → mold preforming → high temperature curing → traction cutting → surface treatment.

Parameters: curing temperature 150-200℃, traction speed 0.5-2m/min, to ensure that the product is dense and free of bubbles.

2. Technical advantages

Automated production: full CNC equipment ensures dimensional accuracy (error ≤0.5mm).Environmentally friendly process: zero VOC emissions, in line with GB/T 31539-2015 standards.

Contact Us

Keywords: