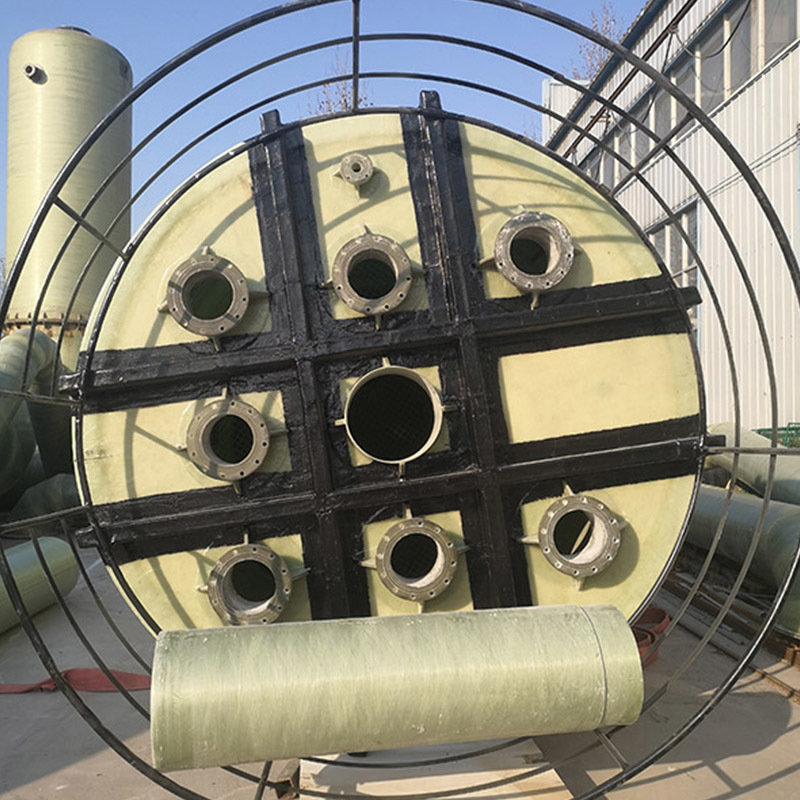

FRP Pipes for Acid Mist Purification and Absorption Projects

FRP pipes for acid mist purification and absorption (FRP pipes) are high-performance composite pipes designed for corrosive gas treatment systems. They are made of resin matrix and glass fiber reinforced materials. Its excellent chemical corrosion resistance, light weight, high strength and long life make it the core conveying component of acid mist purification systems in chemical, metallurgical, electroplating and other industries. It can efficiently convey highly corrosive gases such as sulfuric acid, hydrochloric acid, nitric acid and mixed waste gas.

Features & Advantages

Performance indicators Parameters/characteristics

Temperature range -40℃ ~ +120℃ (customizable high temperature resistant models)

Pressure rating PN0.6~2.5MPa

Corrosion resistance Tolerant to acid and alkali media with pH1-14

Tensile strength ≥300MPa

Thermal conductivity 0.23W/(m·K) (only 1/100 of steel pipe)

Life cycle More than 20 years (acidic environment)

Application

Key industries: titanium dioxide production, battery manufacturing, acid regeneration plant

Emerging fields: lithium battery material processing, semiconductor etching waste gas treatment

Renovation project: Replacement of high temperature and strong corrosion conditions of traditional PP/PVC pipes

FRP Pipe for Acid mist treatment system

Spray tower inlet/outlet pipes, fan connection pipe section

FRP Pipe for Industrial waste gas treatment

FRP Pipe for Chromium acid mist collection in electroplating plants, acid washing waste gas transportation in phosphating lines

FRP Pipe for Environmental protection equipment

FRP Pipe for Wet electrostatic precipitator (WESP) shell, desulfurization tower circulation pipeline

Tag:

Previous

Next

Previous:

Next:

Related Posts

Product specifications and services of FRP grating