Analysis of the Characteristics and Applications of Vertical FRP Storage Tanks

Vertical FRP storage tanks are a common type of industrial storage equipment. With their unique material advantages and structural design, they have been widely applied in the fields of chemical engineering, environmental protection, and food processing in Heilongjiang region. This article will introduce FRP storage tanks from aspects such as their characteristics, production processes, applicable scenarios, and maintenance points, to help readers better understand this equipment.

#1. Material properties of FRP storage tanks

Fiberglass reinforced plastic (FRP), also known as fiber-reinforced plastic, is composed of glass fibers and resin. This material has the following characteristics:

- Strong corrosion resistance: It can withstand various chemical media such as acids, alkalis and salts, and is suitable for storing corrosive liquids.

- Light weight and high strength: Compared with metal storage tanks, fiberglass reinforced plastic has a lower density but excellent mechanical properties, making it easy to transport and install.

- Long service life: Under normal usage conditions, the service life of FRP storage tanks can usually reach more than 10 years.

- Good insulation performance: Non-conductive, suitable for storage requirements in special environments.

#2. Design Advantages of Vertical Structure

Vertical FRP storage tanks are installed vertically. Their design features include:

- Space-saving: It occupies a small area and is suitable for factories or workshops with limited space.

- High stability: The bottom is usually designed as flat or conical, and when combined with the support structure, it can enhance wind resistance and earthquake resistance.

- Facilitates stratified storage: Different liquids can be classified and stored by installing some internal partitions.

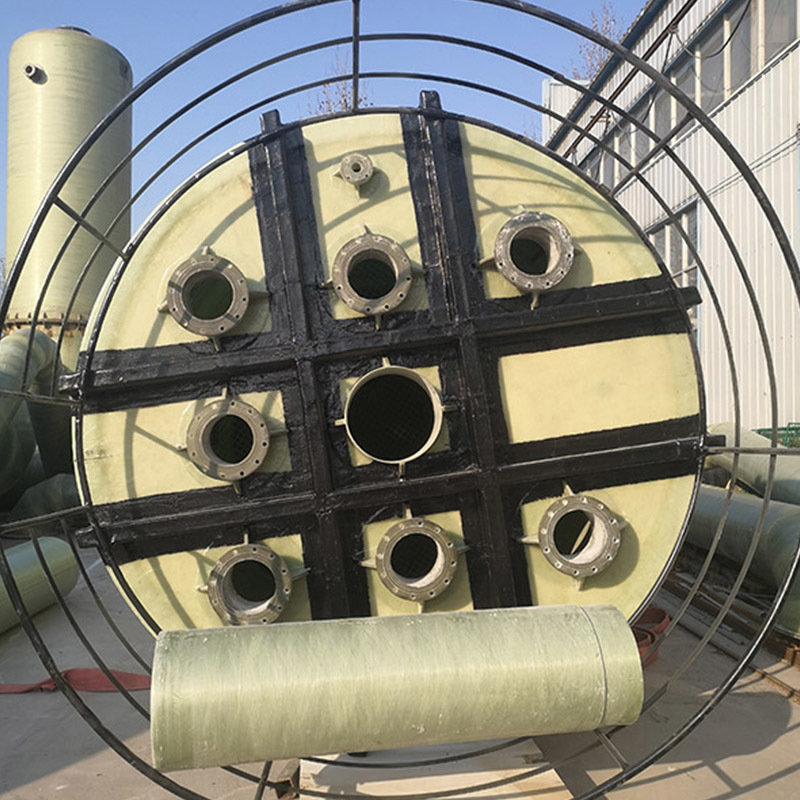

#3. Production Process and Quality Control

The production of FRP storage tanks mainly adopts hand lay-up molding, winding molding and other processes. The key links include:

- Mold making: Customize molds according to customer requirements to ensure precise dimensions.

- Lamination process: By laying glass fiber cloth layer by layer and coating it with resin, a uniform tank structure is formed.

- Curing and Inspection: After curing, air tightness and strength tests must be conducted to ensure there is no leakage or defect.

#4. Main application fields

In the Heilongjiang region, vertical FRP storage tanks are often used in the following scenarios:

- Chemical industry: Store corrosive chemicals such as hydrochloric acid and sulfuric acid.

- Water treatment: Used as a sewage treatment pool or a clear water storage tank.

- Food processing: For storing non-corrosive liquids such as soy sauce and alcoholic beverages, food-grade resin standards must be met.

- Agricultural irrigation: Used for water storage or storage of fertilizer solutions.

#5. Installation and Usage Precautions

To ensure the safe operation of the storage tank, the following matters should be noted:

- Level foundation: Before installation, the ground must be compacted to prevent the tank from deforming due to settlement.

- Avoid overpressure: Use according to the design pressure and do not increase the internal load at will.

- Regular inspection: Inspect the tank body at least once a year for any cracks or signs of aging.

#6. Maintenance and Common Problem Handling

The maintenance of FRP storage tanks is relatively simple, but it should be noted that

- Cleaning method: Use a soft cloth or a low-pressure water gun to clean, and avoid scratching the surface with hard objects.

- Minor repairs: If local damage is found, it can be repaired with special resin materials.

- Winter protection: The winter in Heilongjiang region is cold. The liquid in the tank needs to be drained to prevent it from cracking due to freezing.

#7. Comparison with storage tanks of Other materials

Compared with metal or plastic storage tanks, the advantages of FRP storage tanks lie in:

- Lower overall cost: Although the initial investment may be slightly higher, the long-term maintenance cost is lower.

- Wider adaptability: It is both corrosion-resistant and has high structural strength.

When making a purchase, users should determine the specifications and materials based on their actual needs and follow the correct installation and maintenance methods to extend the service life of the equipment. Through rational application, FRP storage tanks can provide reliable guarantees for production and operation.

Tag:

Related Posts

Product specifications and services of FRP grating